Warehouse safety: from regulation to ergonomics

Table of Contents

In the fast-paced world of warehouse and industrial environments, ensuring workers protection is essential. The Occupational Safety and Health Administration (OSHA) plays a key role in shaping the future of workplace safety by setting strict standards to protect employees in various industries. In this article, we examine the intricacies of OSHA compliance in warehouse environments, with a special focus on guardrails, loading ramp protection, and the overall evolution of workplace safety.

Warehouse safety in compliance with OSHA

The Occupational Safety and Health Administration, established in 1971, is a trusted partner for workplace safety in all industries. In the warehouse context, OSHA compliance involves adherence to a set of regulations designed to mitigate hazards and ensure the well-being of workers. These regulations cover a wide range of safety measures, from equipment maintenance to employee safety training.

Shedding light on the reality of warehouse safety

Before exploring the specifics of OSHA compliance, it is essential to understand the severity of workplace safety issues in the warehouse industry. According to recent statistics, this sector faces a notable rate of occupational injuries and illnesses. An estimated 197,100 injuries and 112 deaths in storage environments were reported in 2021 alone.

These figures underscore the urgent need for stringent safety measures and regulatory compliance to protect the workforce.

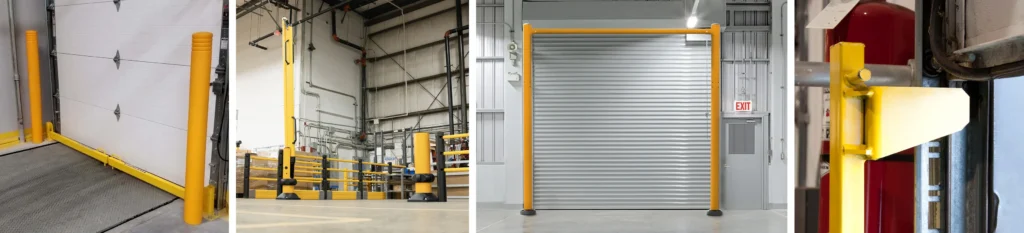

Protective barriers: Protecting the work environment

One of the key areas where OSHA compliance is rigorously applied in warehouse environments is the installation of protective barriers. These guard rails serve as a physical barrier to prevent accidental falls, collisions, and other potential hazards. OSHA regulations stipulate specific height, strength, and spacing requirements for barriers to ensure their effectiveness in creating a safe work environment.

Implementing guard rails and safety barriers not only complies with OSHA standards, but also contributes to a culture of people safety within the workplace. By providing a visible and tangible safety measure, guard rails act as a constant reminder of the importance of adhering safety protocols.

The critical role of loading dock protection

Loading docks are busy areas in warehouses, making them prone to accidents if not properly secured. OSHA mandates strict guidelines for load area protection to mitigate the risks associated with the movement of goods and equipment. For loading and unloading activities at warehouse dock doors, safety measures include:

- Visible signage emphasizing safety instructions and potential hazards;

- Protective barriers to shield workers and equipment from potential impacts;

- Designated areas that establish routes for pedestrians and vehicles to minimize the risk of collisions;

- Proper lighting to enhance visibility during loading and unloading operations;

- Dock Levelers to ensure a smooth transition between dock and trailer.

Failure to comply with dock area safety and equipment protection not only puts workers at risk, but also jeopardizes the efficiency of warehouse operations. Implementing loading dock safeguards not only aligns with regulatory requirements, but also enhances overall operational efficiency and employee well-being.

Prioritizing employee well-being with ergonomics in industrial environments

Ensuring a safe and healthy working environment in warehouses goes beyond conventional safety measures – it extends to the thoughtful integration of ergonomic principles. Ergonomics, the science of designing workspaces to suit workers’ capabilities, plays a critical role in minimizing the risk of musculoskeletal disorders (MSDs) and other workplace injuries.

OSHA recognizes the critical importance of ergonomics in warehouse environments, emphasizing the need for compliance, proactive assessment and management of ergonomic risks.

Key components of ergonomic warehouse safety:

- Proper lifting techniques: training employees on correct lifting methods to reduce the risk of musculoskeletal injuries and emphasizing the importance of ergonomic lifting aids and tools to reduce strain.

- Ergonomic equipment: Providing workers with tools and machinery designed to minimize physical stress and fatigue, while using adjustable workstations and tools tailored to individual needs for enhanced comfort.

- Designing comfortable and efficient workstations: creating workstations that promote optimal posture and reduce muscle strain.

Embedding ergonomic principles into daily operations transforms the approach to safety, making it an integral part of warehouse activities. By prioritizing employee well-being through ergonomics, warehouses can create a safer, healthier, and more productive work environment.

The role of warehouse protections in the evolution of safety

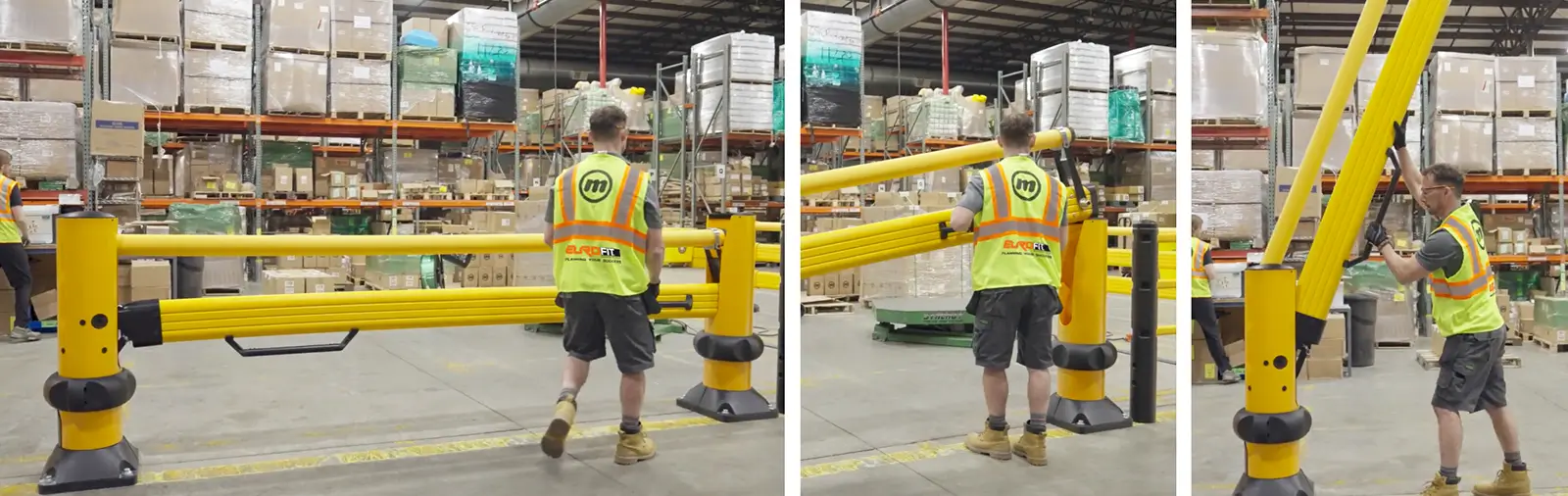

As safety standards evolve, innovative solutions become crucial to meeting and exceeding regulatory requirements. Therefore, the Safety Solutions offered by EUROFIT are specially designed to prevent accidental collisions and to protect both people and equipment in dynamic warehouse environments. Also, the state-of-the-art technology in our McCue brand safety solutions not only aligns with current legislation, but even exceed expectations, providing a superior level of protection in incident-prone areas (especially related to forklifts) and setting a new safety standard in warehouse operations.

Navigating the Future of Warehouse Safety

In conclusion, OSHA compliance is the bedrock of warehouse safety, creating the context for a secure and productive work environment. Whether we are talking about protective barriers, bollards, protection for racks or columns, anti-fall protection netts, warehouse partitions, protection against chemical liquids, protection of the docking area or ergonomic considerations, they are all integral components of Occupational Safety and Health Administration regulations, contributing to the overall goal of protecting workers in industrial environments, providing a safer and more efficient workplace for all.

“Every expense and energy invested in workplace safety solutions serves one sole purpose: to ensure that at the end of a workday, all employees return home safely to their families, just as they left in the morning.”

In line with this motto, our company has implemented the international standard ISO 45001:2018 (Occupational Health and Safety Management System), committing ourselves to continuously improving performance in health and safety at the workplace.