Warehouse Automation: The Impact of AI and IoT on Efficiency and Innovation

In a constantly changing world where technology advances rapidly, logistics is becoming an increasingly complex and challenging field. Intelligent logistics centers represent a significant evolution in managing supply chains, using advanced technologies to improve storage and distribution processes. These technologies not only enhance operational efficiency but also radically transform how companies conduct their business.

In this article, we will explore how AI (Artificial Intelligence) and IoT (Internet of Things) influence warehouse automation and what benefits these innovations bring. IoT and AI are two of the key technologies of Industry 4.0, also known as the Fourth Industrial Revolution.

The integration of IoT and AI acts as a true engine of transformation in the logistics field. IoT sensors collect data from the entire logistics network, while AI analyzes this data, generating valuable insights that can be used to improve operational efficiency. For example, an IoT system can monitor the temperature and humidity of a warehouse, and AI can analyze this data to determine the best conditions for storing various items.

Therefore, the main technologies used in intelligent warehouses are:

- Internet of Things (IoT)

- Artificial Intelligence (AI)

- Warehouse Management Systems (WMS)

- Radio-Frequency Identification (RFID) technology

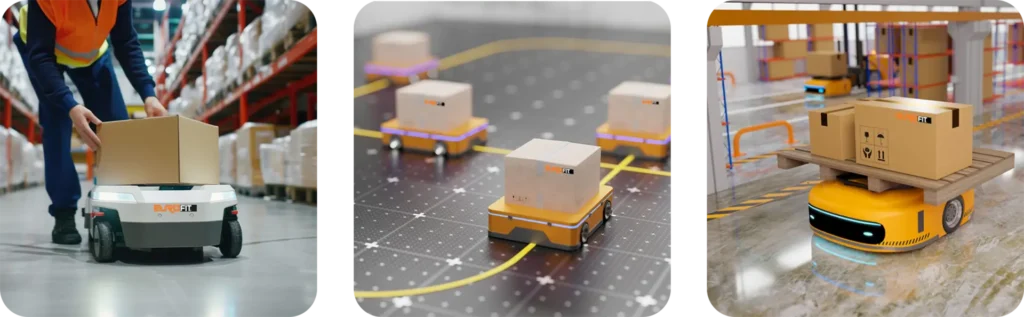

- Robots and Automated Guided Vehicles (AMR / AGV)

- Big Data and Predictive Analytics.

The Role of IoT in Warehouse Automation

- Real-time inventory monitoring – One of the most evident examples of IoT usage in logistics is inventory monitoring, transforming the shelves you have in your warehouse into smart shelves. Distance sensors can be placed on shelves to track stock levels in real time. These sensors can send alerts when stock levels fall below a certain threshold, automatically initiating restocking orders. This automation reduces the risk of stockouts and minimizes costs associated with overstocking.

- Equipment verification in the warehouse – IoT also enables efficient equipment management. Sensors can monitor the condition of machinery and detect issues before they become critical. For example, a vibration sensor can indicate an impending motor failure, allowing maintenance to be scheduled before the equipment completely breaks down. This proactive approach reduces downtime and repair costs.

- Improving safety and security in logistics centers – IoT plays a crucial role in maintaining safety and security in logistics centers. IoT sensors can monitor environmental conditions, such as temperature and humidity, to protect perishable or sensitive goods. Additionally, sensor-based security systems can detect unauthorized movements or access to restricted areas, sending real-time alerts to security personnel. This continuous monitoring helps prevent theft and damage to items, ensuring the integrity of stock and the safety of employees.

The Impact of AI on Storage Processes

- Predictive analytics – Artificial intelligence means that machines, particularly computers, mimic the way humans think and make decisions. AI can analyze large amounts of data, identifying patterns and trends that can be used to make informed decisions. In logistics, AI can optimize delivery routes, predict demand, and improve inventory management.

- Process automation – AI can automate various processes in warehouses, from order management to goods handling. Robots equipped with AI can navigate autonomously through the warehouse, identify products, and perform handling tasks (loading and unloading). This not only optimizes the time taken to carry out operations but also minimizes the risks of employee injuries.

- Improving teamwork – AI can support collaboration among warehouse teams by providing real-time information and updating data on inventory and deliveries. This enables employees to make quicker and more informed decisions, thereby improving operational efficiency.

- Cost reduction – The implementation of IoT and AI in logistics has a significant impact on costs and operational efficiency. Automating processes reduces the need for human intervention, thereby minimizing errors and increasing the speed of operations. Additionally, by continuously monitoring resources, companies can reduce storage costs and optimize equipment usage (for example, automatically optimizing lighting, heating, or cooling systems to reduce energy consumption). While there is no universally accepted exact figure, some estimates suggest that savings of costs can reach up to 30% or even 50% in some cases, depending on the specifics and complexity of logistics operations and the degree of integration of these technologies. These savings come from reduced delivery times, optimized inventory, and improved equipment management.

- Increased Efficiency – AI and IoT contribute to increased efficiency by reducing the time required for repetitive tasks and improving workflow. This allows employees to focus on value-added activities and utilize their time more efficiently.

As IoT and AI technologies continue to evolve, they are expected to become increasingly integrated into logistics operations. Innovations in artificial intelligence, such as machine learning and predictive analytics, will enable companies to become more agile and adaptable to market changes.

Conclusion

AI and IoT are transforming warehouse automation, adding innovation, efficiency, and sustainability. By integrating these technologies, companies not only improve internal operations but also prepare for the increasingly dynamic future of intralogistics. In a constantly changing world, adopting these solutions becomes essential to remain competitive and meet the ever-increasing demands of customers.

Industry 5.0, which emphasizes societal well-being and sustainability, has been proposed as an evolution of the current Industry 4.0. Regardless of the exact direction, it is clear that the digital transformation of the industry is underway and will continue to revolutionize the way products are designed, manufactured, and distributed in the future.