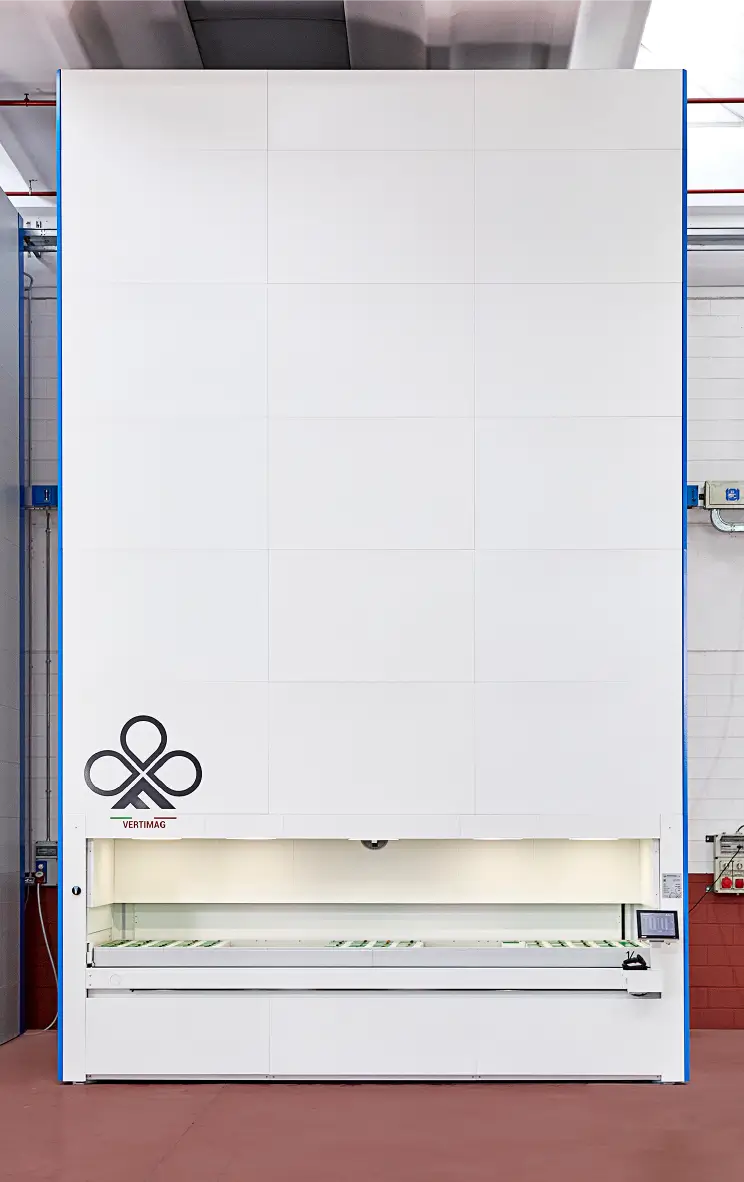

Vertimag

Vertical storage - efficiency, safety and

saving space for warehouses

Versatile, ergonomic, high performance

Vertimag is the ideal solution for storing and handling materials of any shape, weight and size.

Suitable for both semi-finished and finished products, Vertimag optimizes the available height, thus reducing the storage footprint to 1/10 compared to traditional storage systems. The system consists of metal trays handled by an elevator and placed on two opposite sides of the racks.

The flexible configuration of the system allows the positioning of trays with different heights depending on the product to be stored.

When is Vertimag the ideal solution?

- The storage area must be exploited in height;

- The stock mix changes often and there is a need to find a flexible solution to easily adapt to the changing quantities and sizes of stored products;

- The mix of materials requires flexibility: the dimensions and weights of the stored products change over time;

- Picking operations require external material handling equipment;

- Picking and storage operations to prepare different orders require processing single or combined product codes.

The advantages of the Vertimag system

- Ergo-Tech area for picking;

- Anti-seismic structure;

- Suitable for outdoor installation. The presence of an additional structure for plating is not required;

- Ground footprint reduced to 1/10;

- Increased productivity;

- Ideal for materials of different types, weights and sizes;

- Elimination of errors;

- Storage control;

- Risk reduction;

- Ergonomics;

- Increased efficiency.

Why choose the Vertimag system?

Ergonomic:

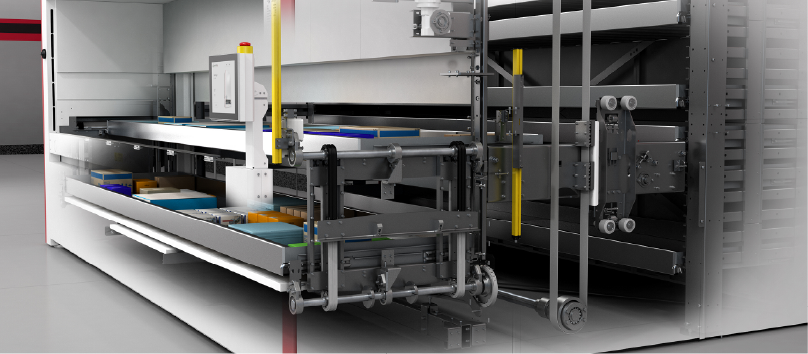

The picking area is positioned at a height of 750 mm from the floor, allowing the operator to handle the products stored in the trays in safe and ergonomic conditions.

Reliable:

The lifting grip system is used to handle the trays, whose special anti-friction devices ensure their proper movement and placement.

Sure:

The tray entry and exit area is equipped with photocells to control tray/material height and ensure operator safety.

Other features of the Vertimag system

- Independent and/or anti-seismic structure for outdoor installation;

- 12″ touchscreen PC with external device ports and easy-to-use GUI;

- The picking area equipped with the work tray is always located at the same height;

- Control of the height of the input material (25 mm step);

- Safety barriers to protect operators;

- The Ergo-Tech system.

Wide range of sizes for every activity

The Vertimag range includes 15 models and 6 types of picking zones.

Thanks to 120 tray combinations, each available with 4 different load capacities, this vertical storage solution can easily adapt to the needs of the most diverse production sectors.

Ask for advice

TYPES OF COMPARTMENTS

In addition to trays and accessories, the type of compartment plays a critical role in picking operations when using a vertical storage system like the Vertimag.

This important aspect is directly related to the need to ensure the best working conditions in terms of safety, ergonomics and efficiency in your warehouse.

Vertimag, for example, can be equipped with 6 types of compartments suitable for different needs:

- Single or double internal compartment;

- Single or double outer compartment;

- Removable compartment;

- The exclusive Ergo Tech system.

Photo gallery

Documentation

Do you have a project? Let's talk!

We are ready to offer you the best solutions for your project!

Contact